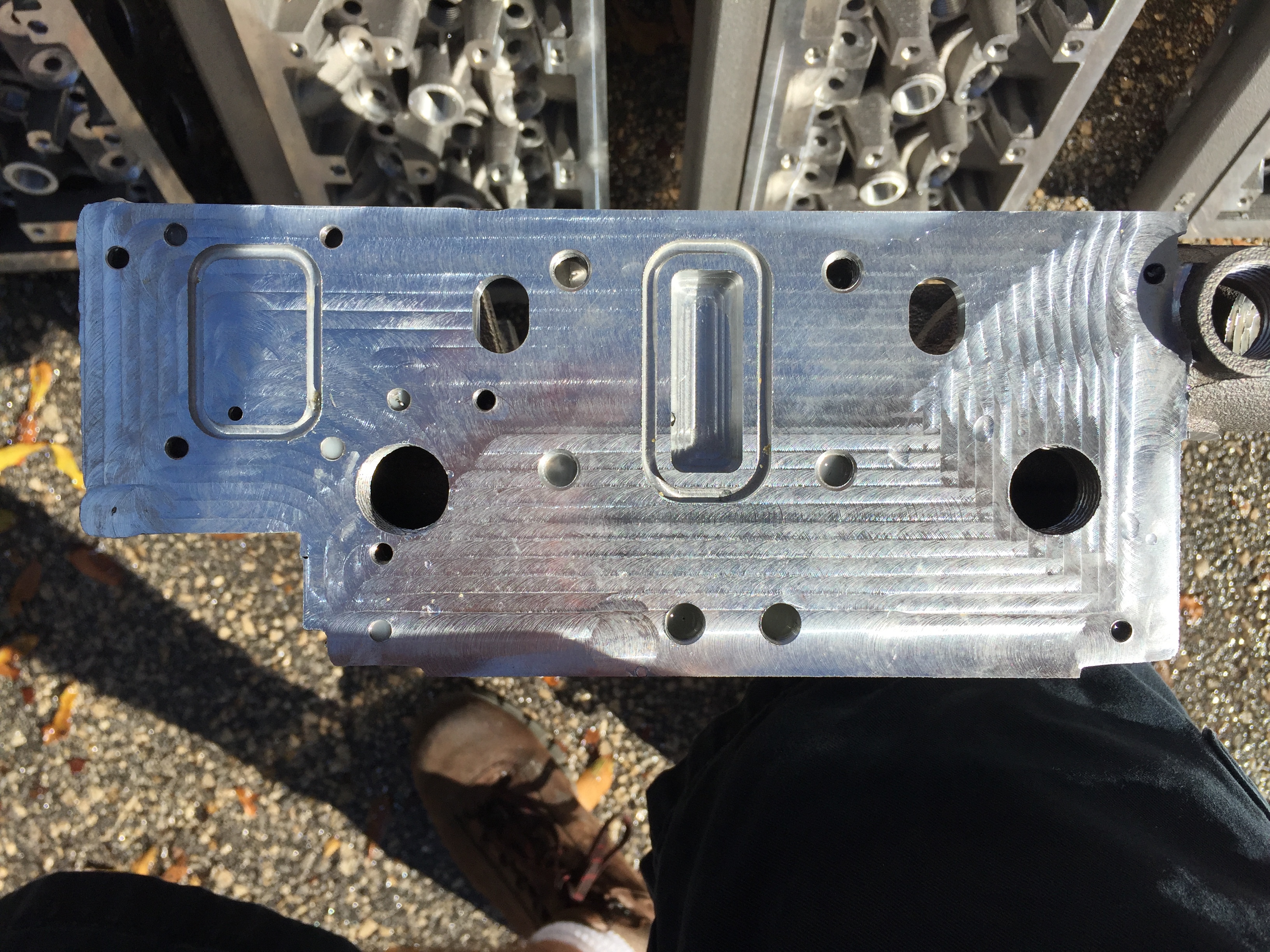

Finished up the manifolds for V3. These were tricky because the owner of V3 decided to make my life miserable tilt the motor the opposite direction. He did this for looks plus he wanted to gain some distance for his induction system. I did a quick check on the 3D model and it looked doable.

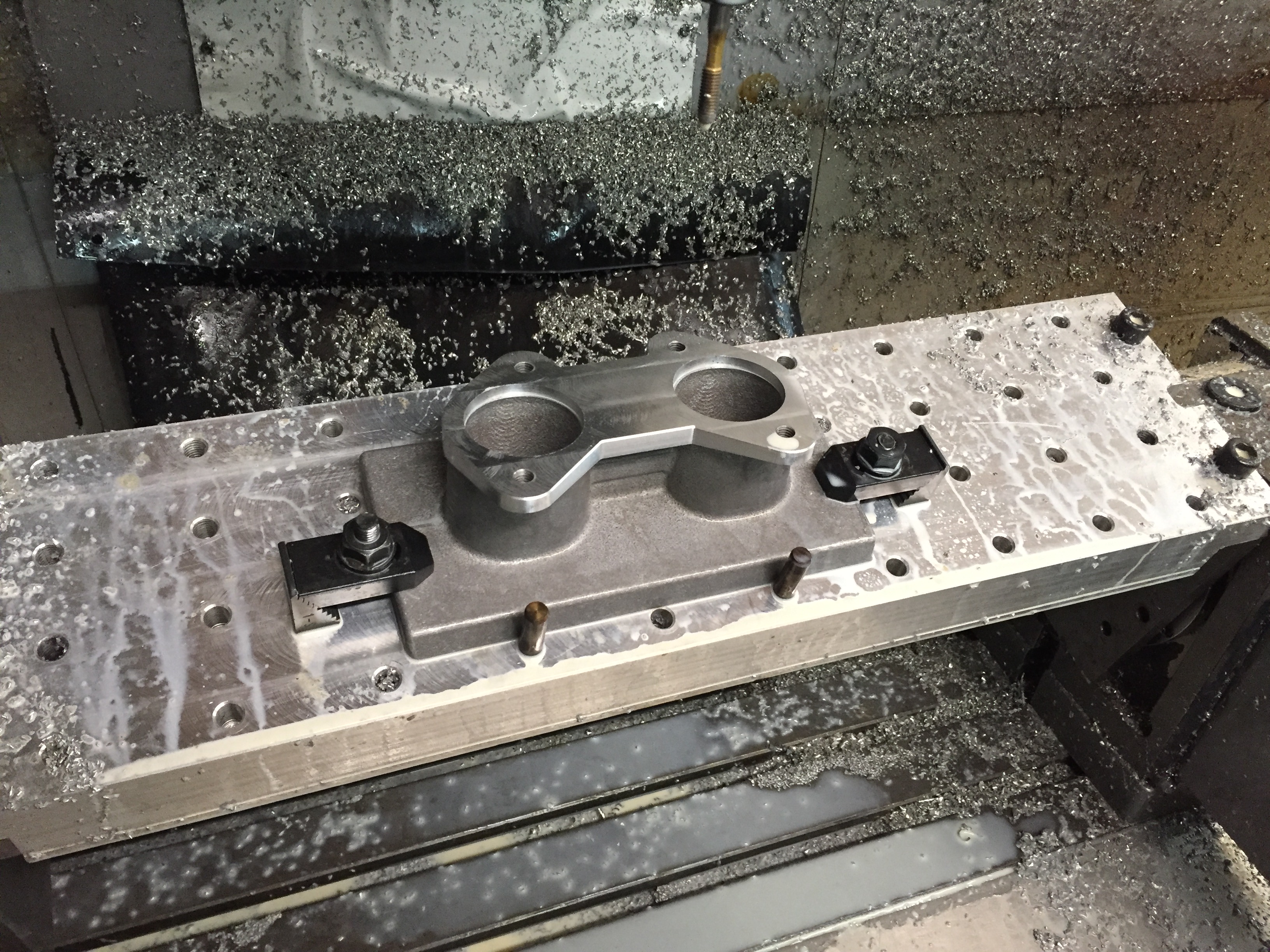

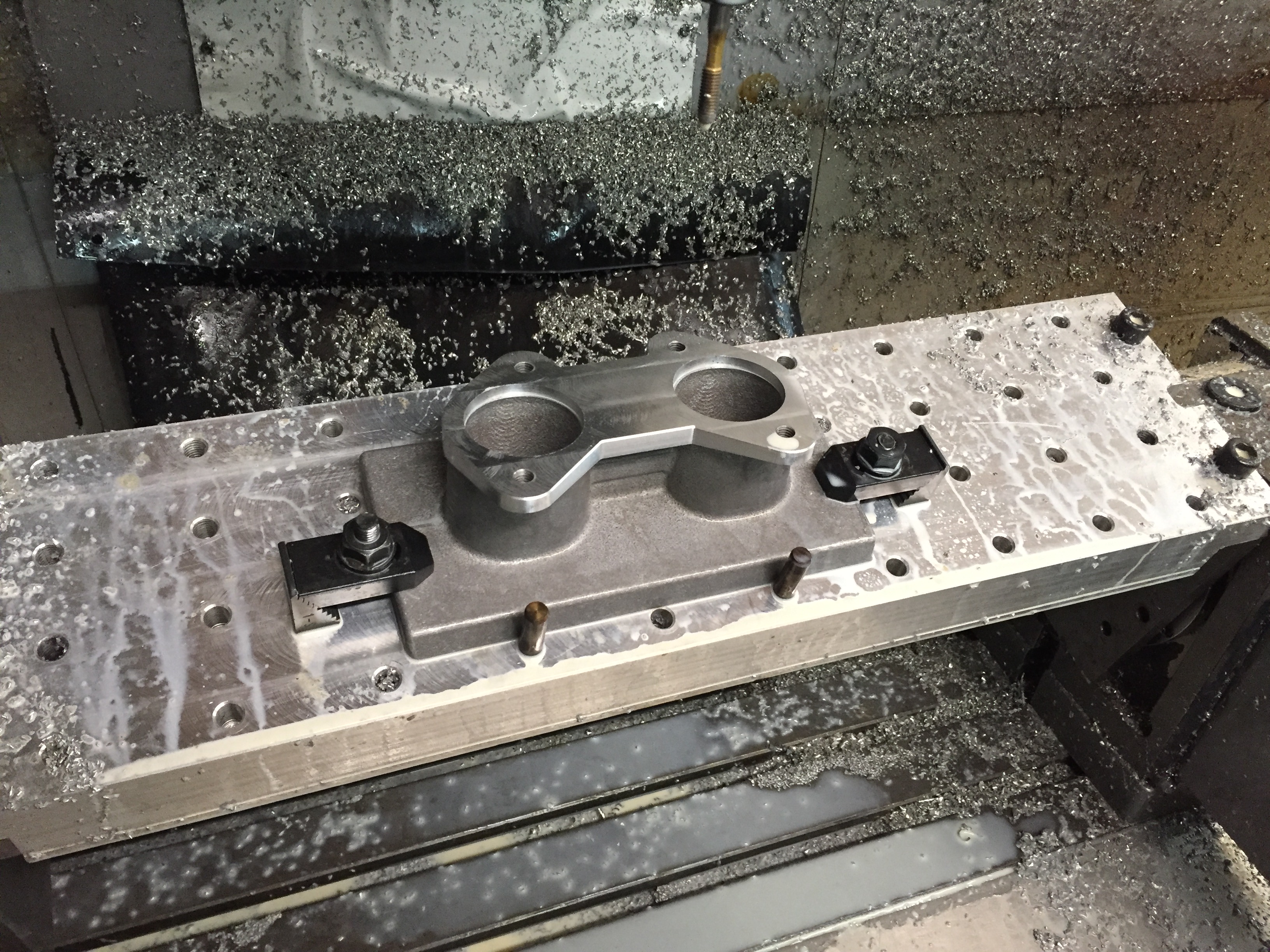

Trunnion plate on the 4th axis comes in handy for this kind of stuff. DCOE pattern matched to 48mm.

Made a quick fixture/index plate to locate off of the DCOE flange. I find most people prefer that their carbs/ITBs line up when they are bolted to the manifold:) Port matched to the head and o-ringed. Rebello will blend the port match into the manifold. Since every build is different I figured the best way to handle it is to cast it a little smaller and then blend as necessary. The ripple pattern you see is from the 3D printed sand. There are certain angles where the layers on 3D printed items are fairly pronounced. I was surprised how well everything worked considering the manifold casting is 180 degrees out from it’s intended angle.

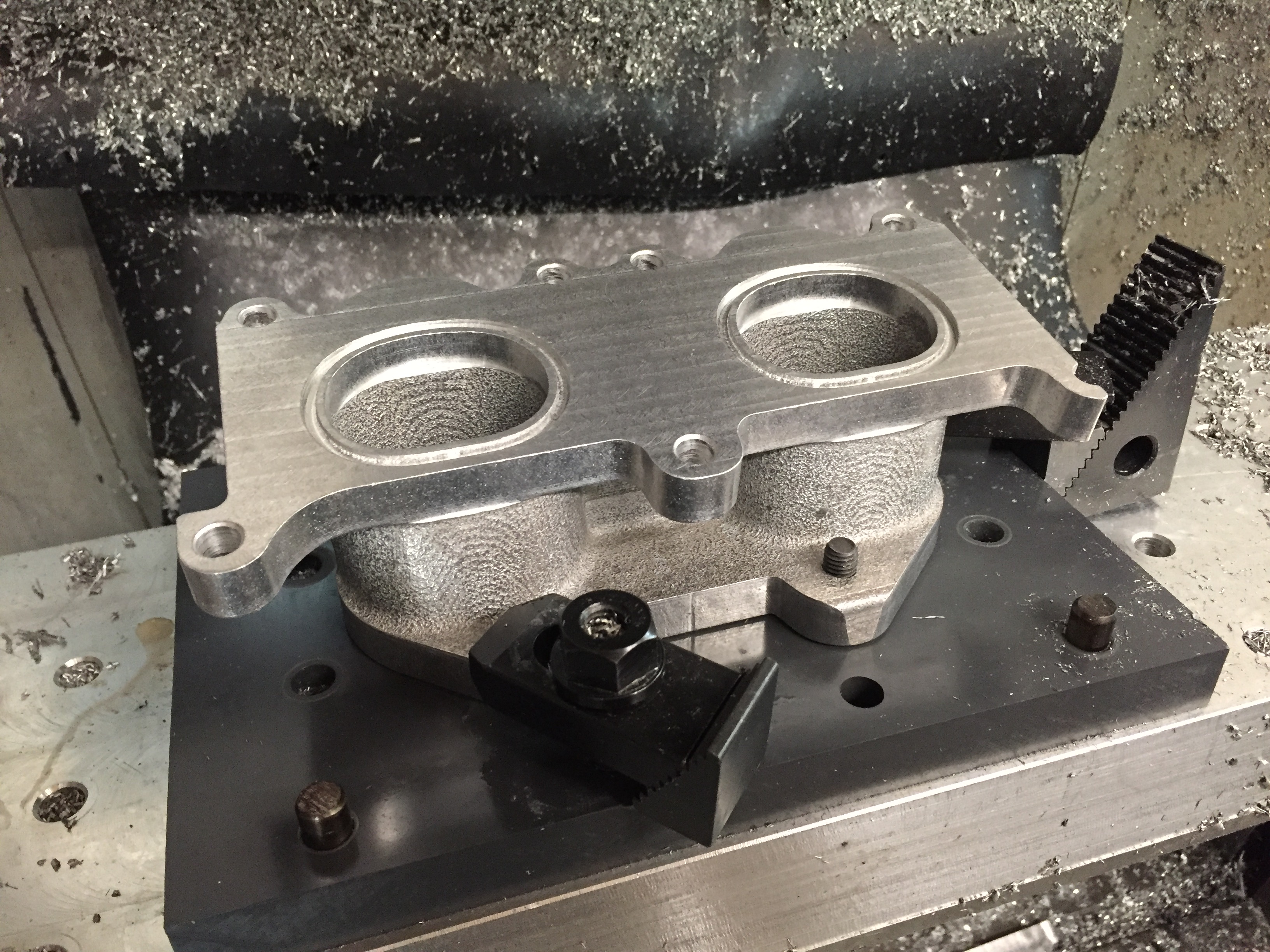

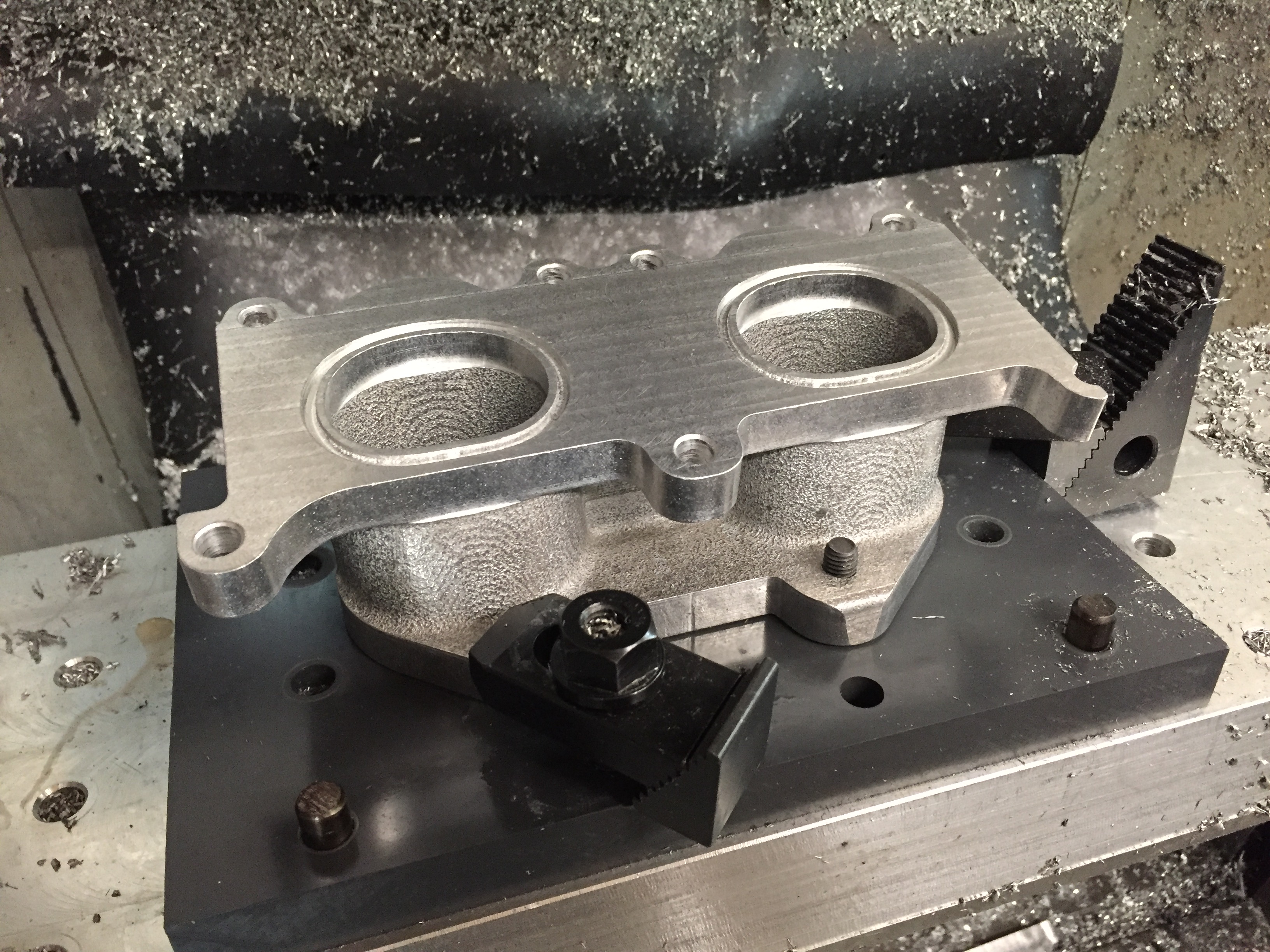

I kind of cheated this shot. The manifold has already been through the vibratory finisher so this is the final finish. I threw it back in the fixture to get the picture.

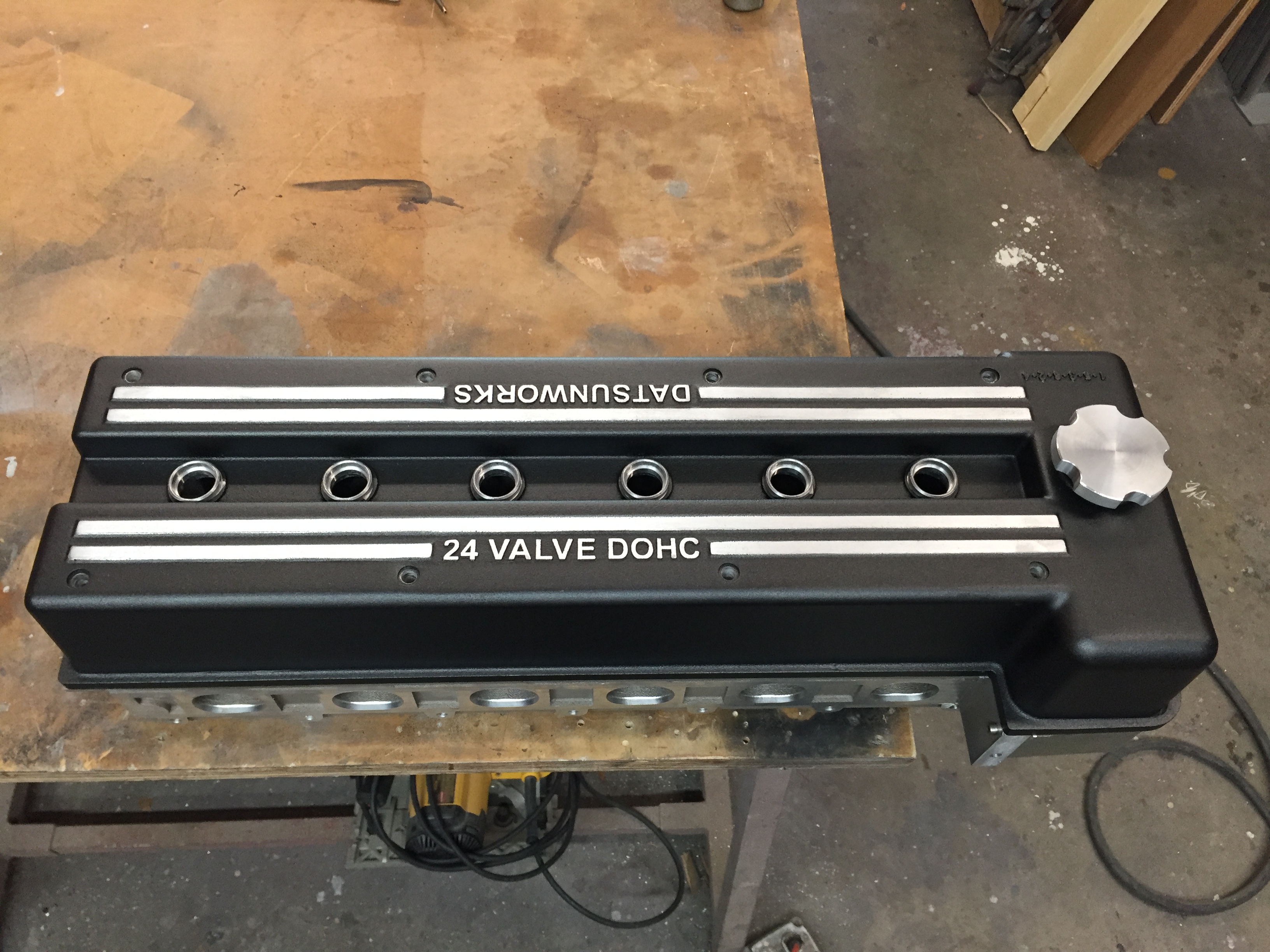

All done and looking pretty!

The manifolds are machined specifically for their position on the head.

Added a rib in the center so that if people have drop link type linkage they can mount the risers to it.

Manifold looks a little fugly in this shot but it really isn’t:)