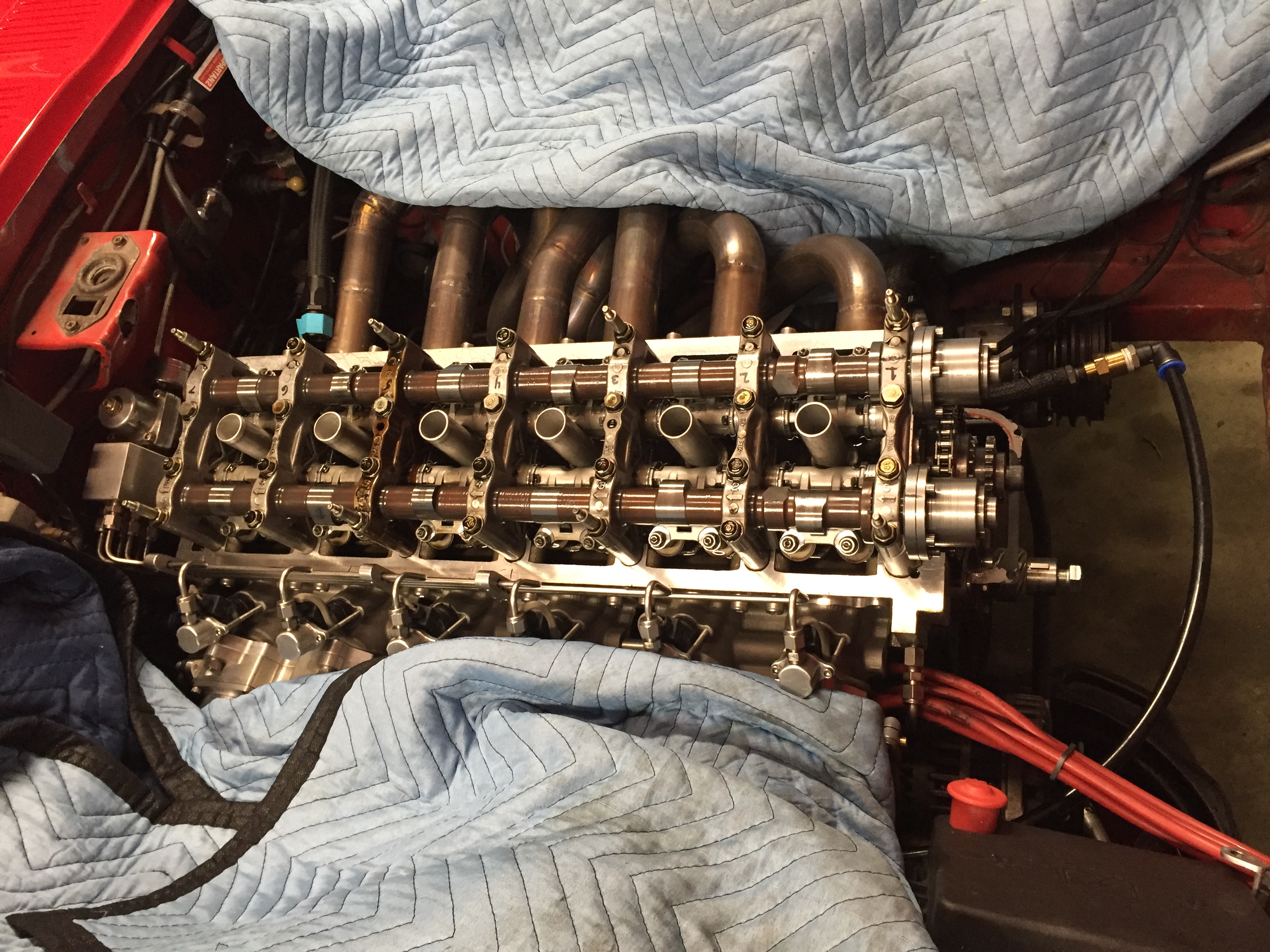

Actually it’s part of a scheduled tear down and inspection. I have around 4200 miles on it. There is some burnishing where the roller meets the lobe. The cam bearing journals are burnished like the used cam towers but no galling.

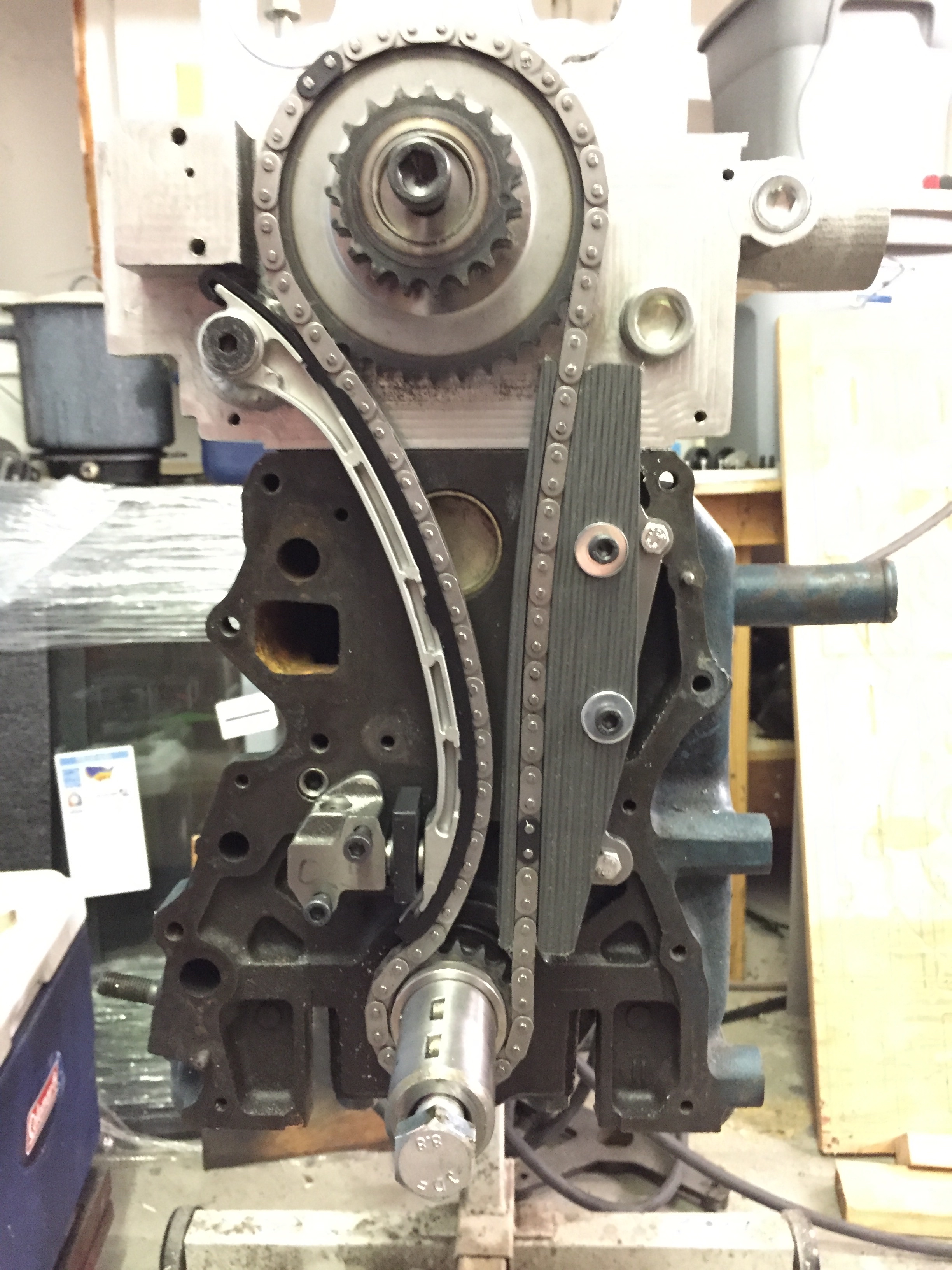

The main reason for the teardown was to rework the lower timing chain. Ever since I converted it from my first version that used the L6 guides to the second version that used the KA24 guides I’ve had an irritating chain noise at idle. At this point I’m pretty sure it was too much slack in the tensioning system. I had already decided to try and implement a curved tension rail to help reduce harmonics. After a bit of screwing around I threw in the towel and designed my own.

Here is a shot of the finished piece on V2. It’s made from nylon 66. I found some references to people making custom guides with it on the internet.

I made a steel plate that bolts to the existing rail holes. I inset the plate into the back of the guide for extra strength.