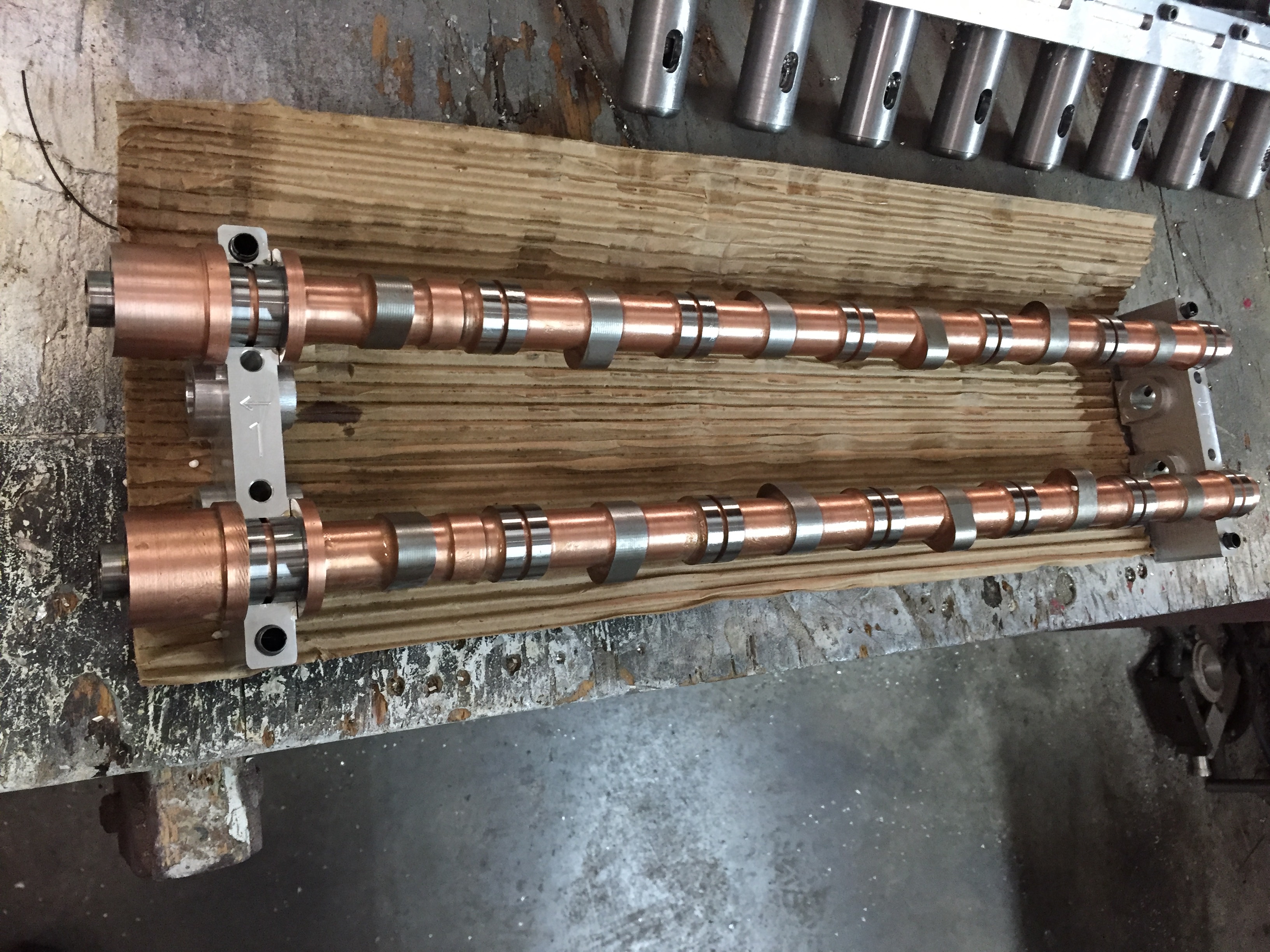

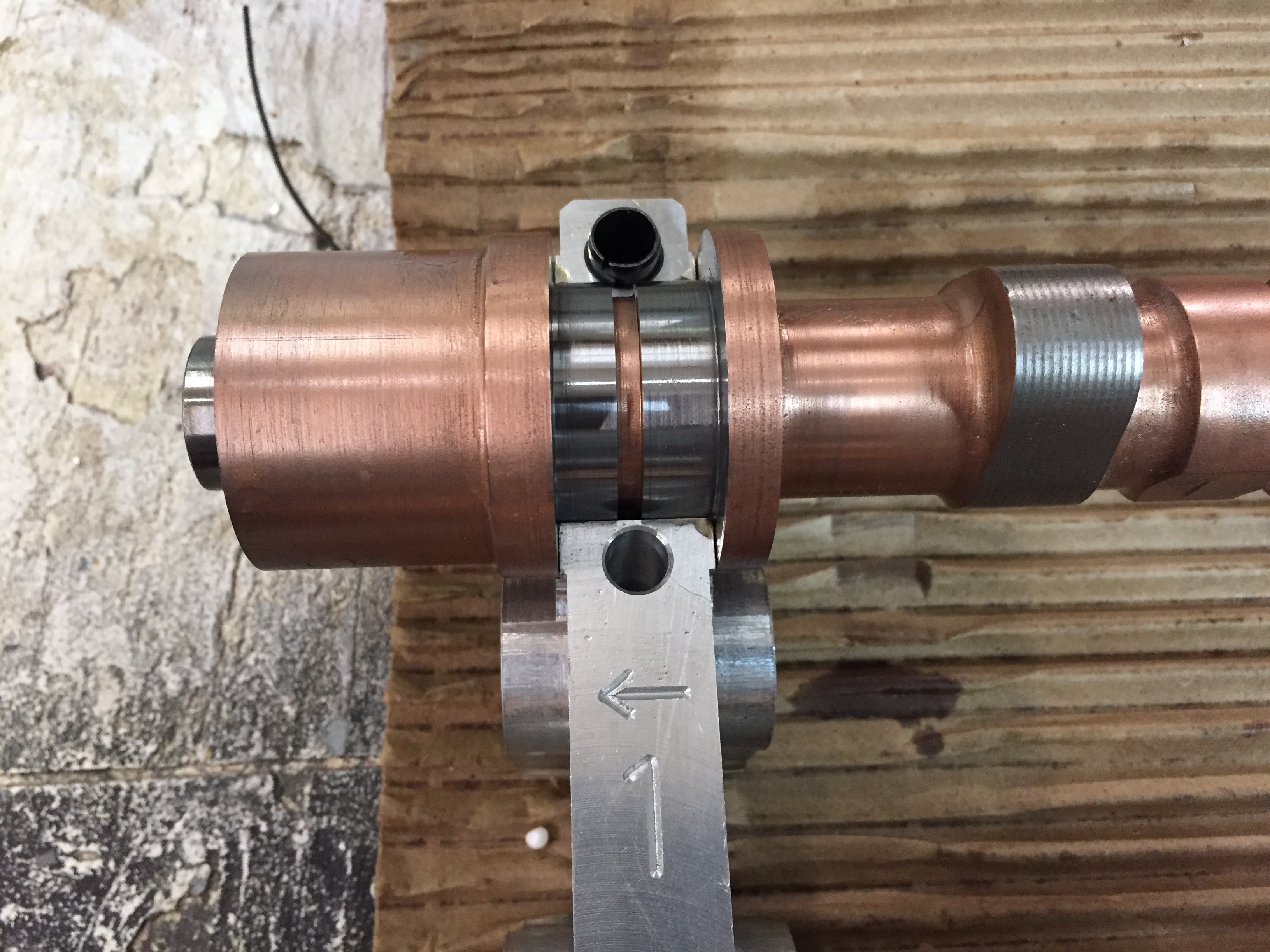

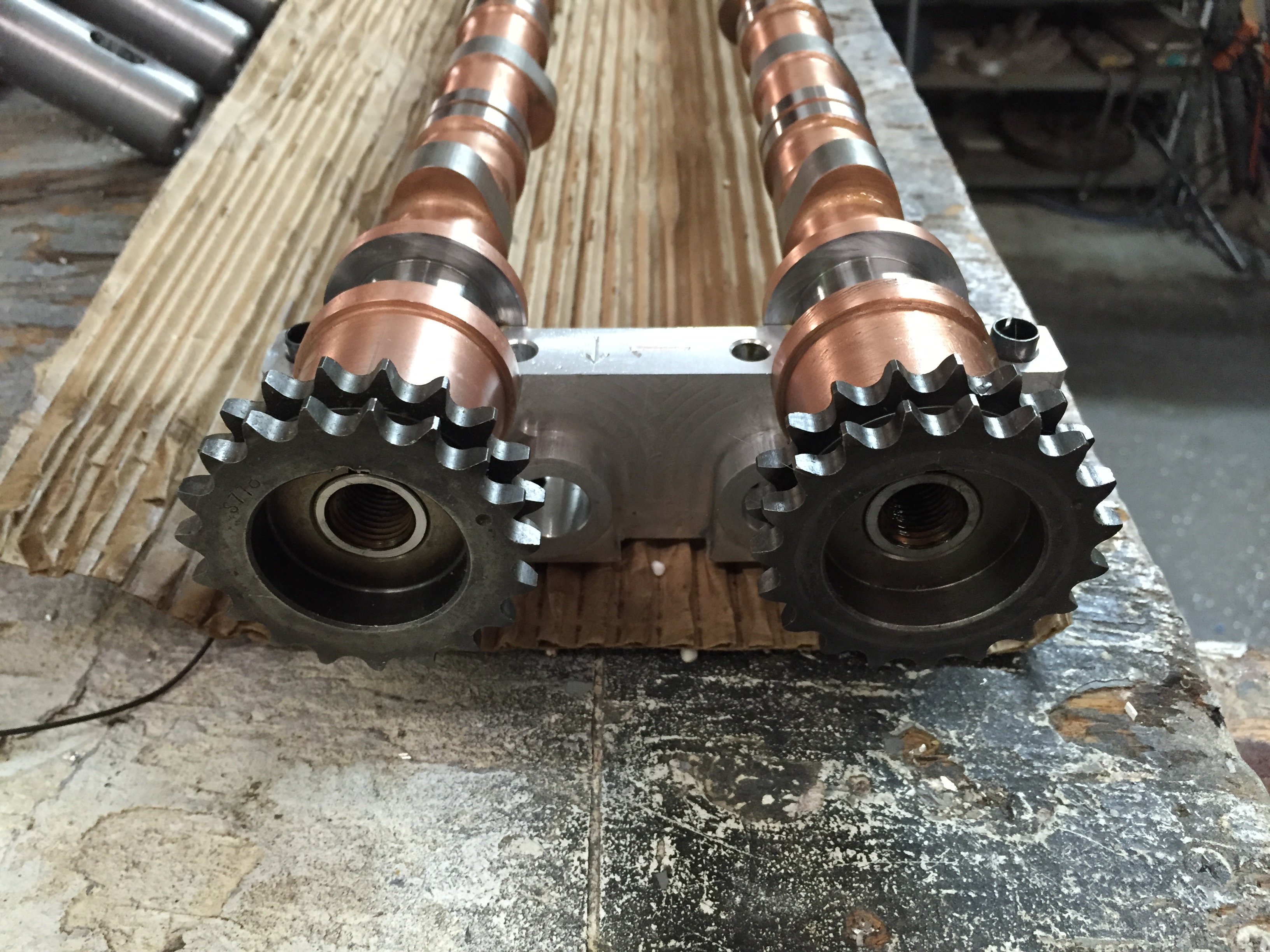

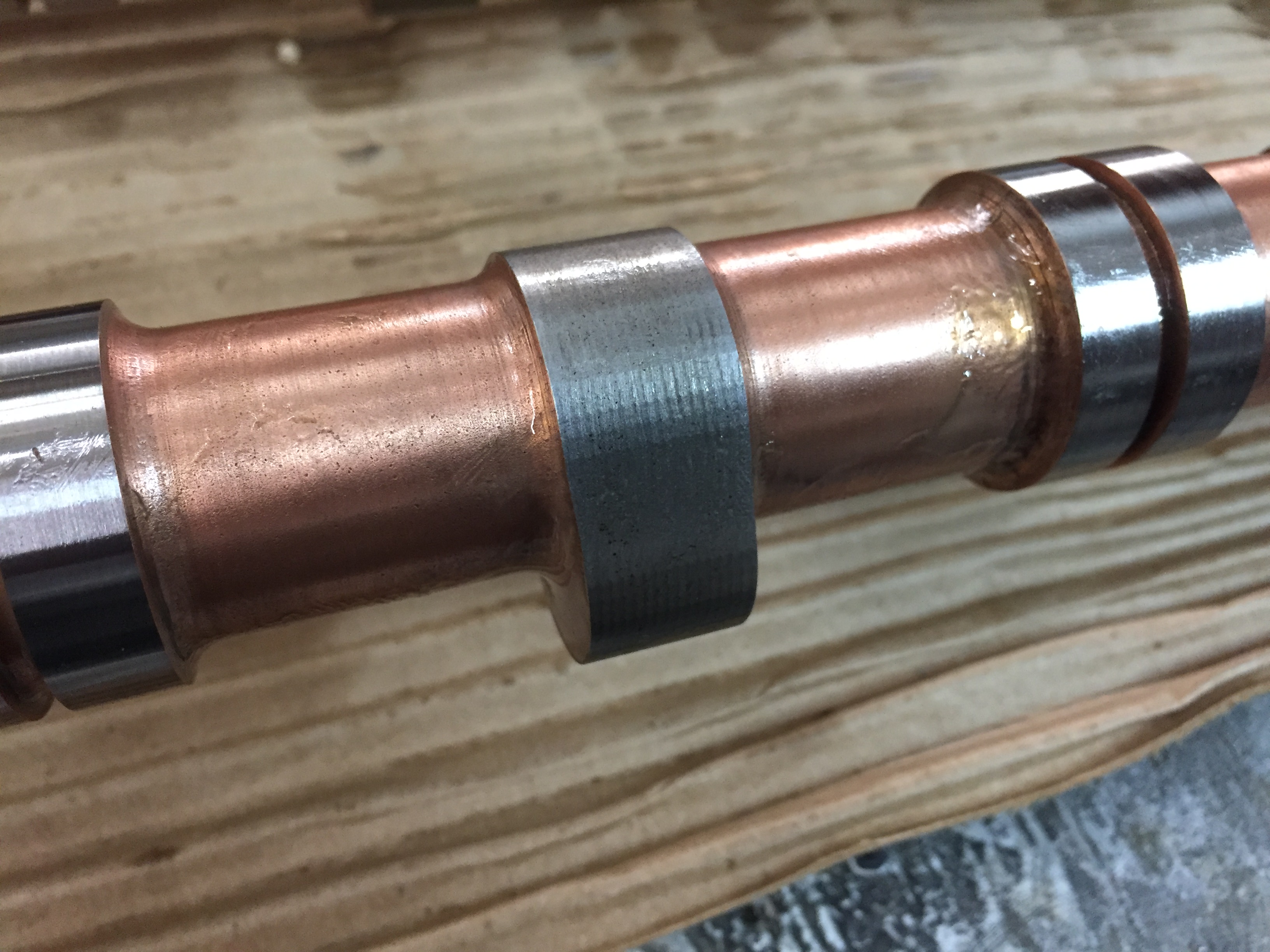

I’ve incorporated the thrust area into the actual cam. The Honda and V1 has a washer that bolts to the cam. This change allowed me to strengthen the front of the cam and also do away with the cam gear adapters.

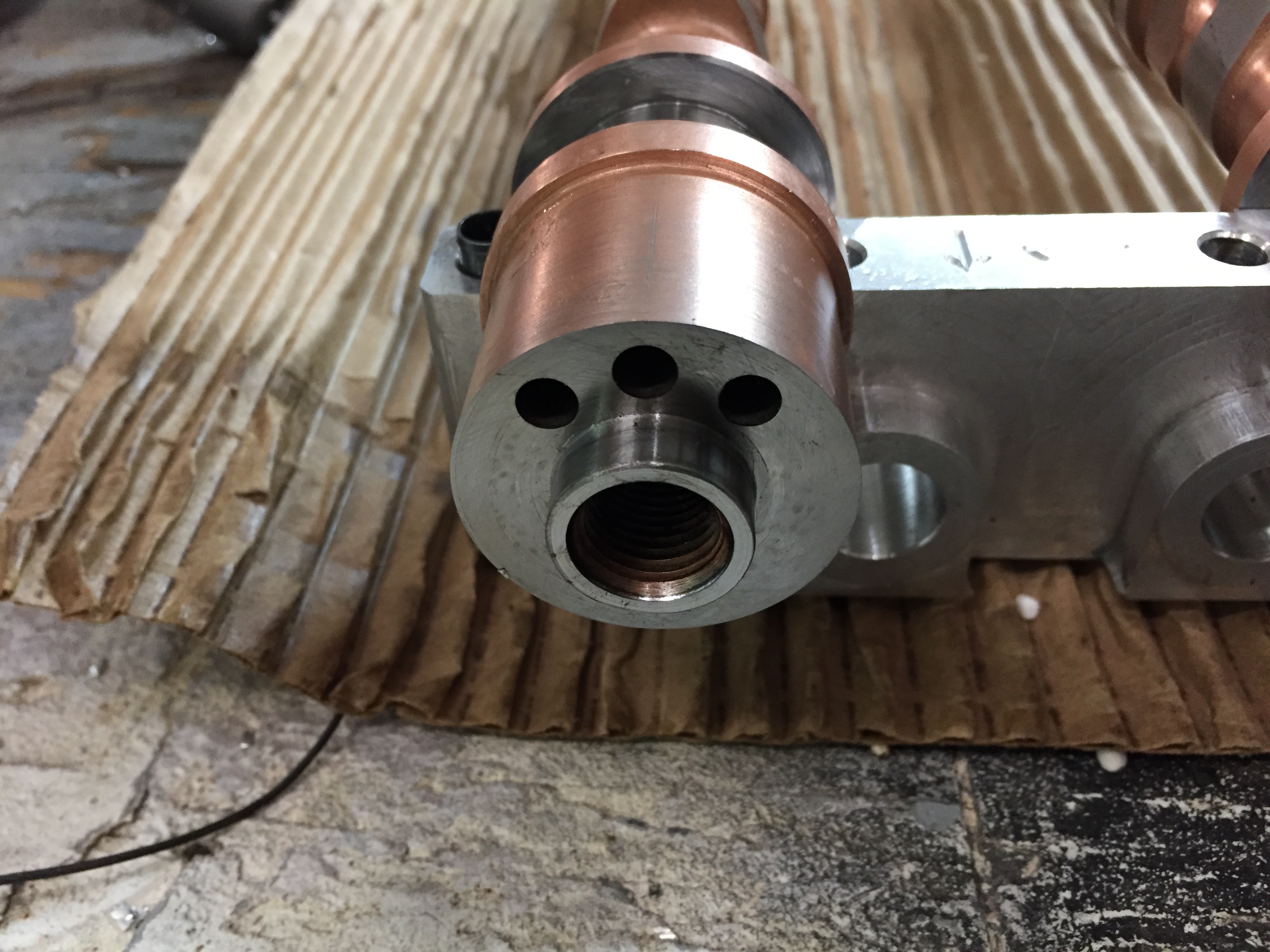

On the front of the cam I had 3 dowel holes drilled. The only way to adjust the cam timing on the K24 is to buy or make modified cam gears with offset dowel holes. The single dowel gives you 2.5 degrees adjustment at the crank per hole. By using three holes I was able to split that to 1.25 degrees advanced and 1.25 degrees retard. This is a big improvement over V1 with the adjustable hubs.

The cam is semi finished from Crane. The lobes will be dialed in buy whomever ends up doing the final grind.