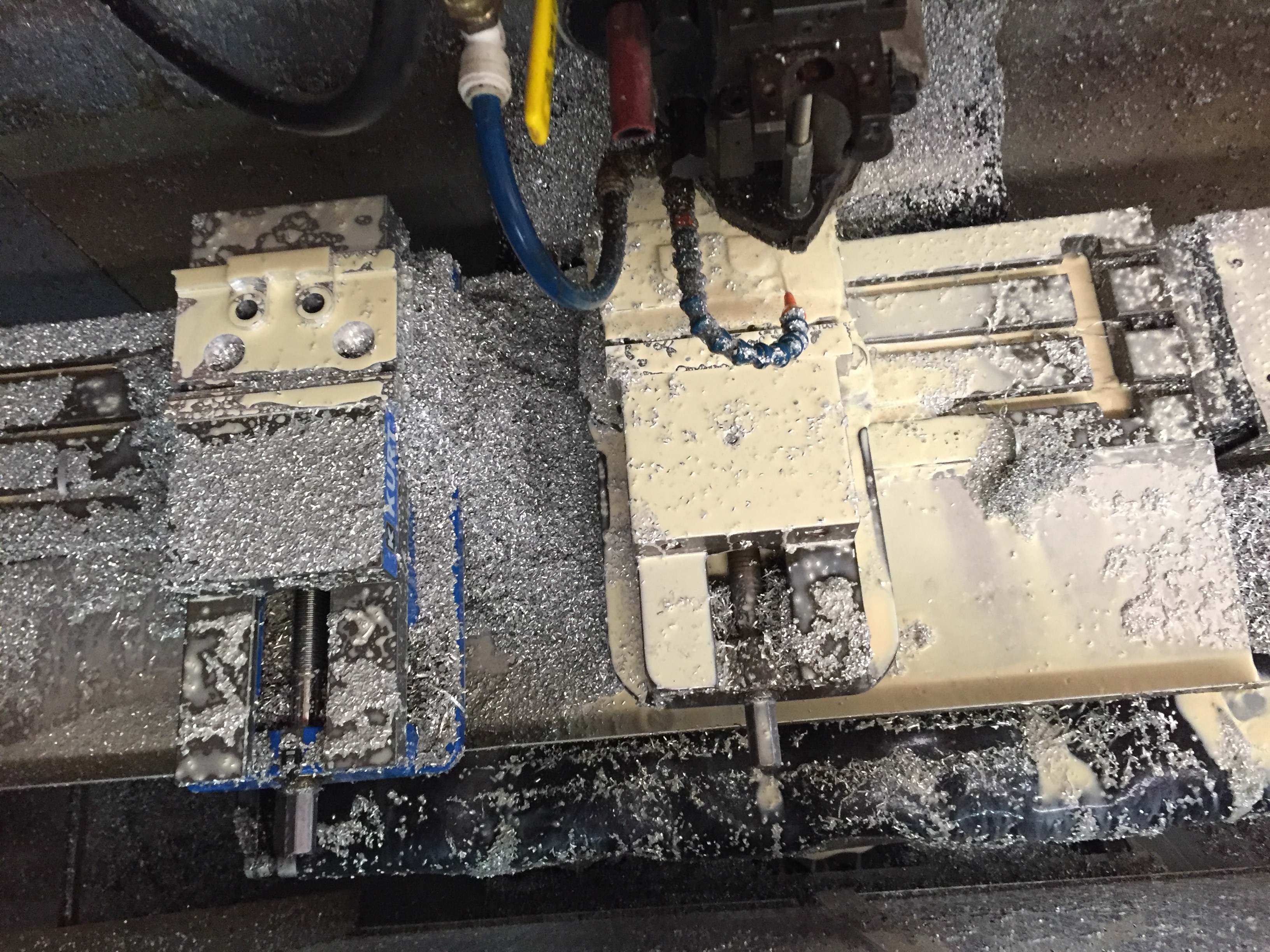

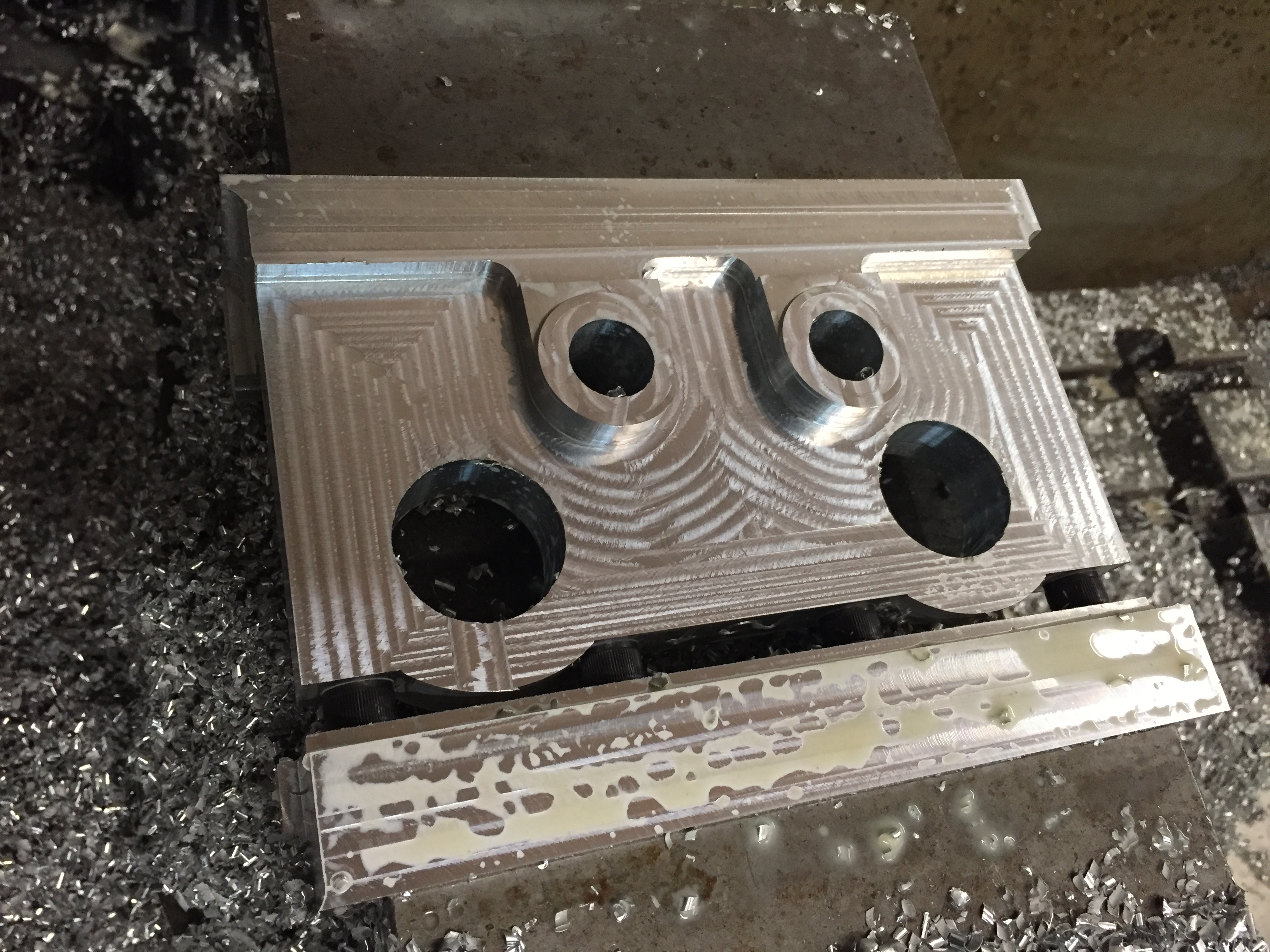

So from V3 forward I have been working on making sure that people who wanted to upgrade to VCT down the road wouldn’t be stuck buying a whole new head. This has turned out to be pretty difficult but not impossible. Complete redesign of the valve cover and modifying the pattern, new timing cover design and pattern, modification to the front of the head and redesign of the cam towers. Finding room to fit two oil delivery systems was the trickiest part.

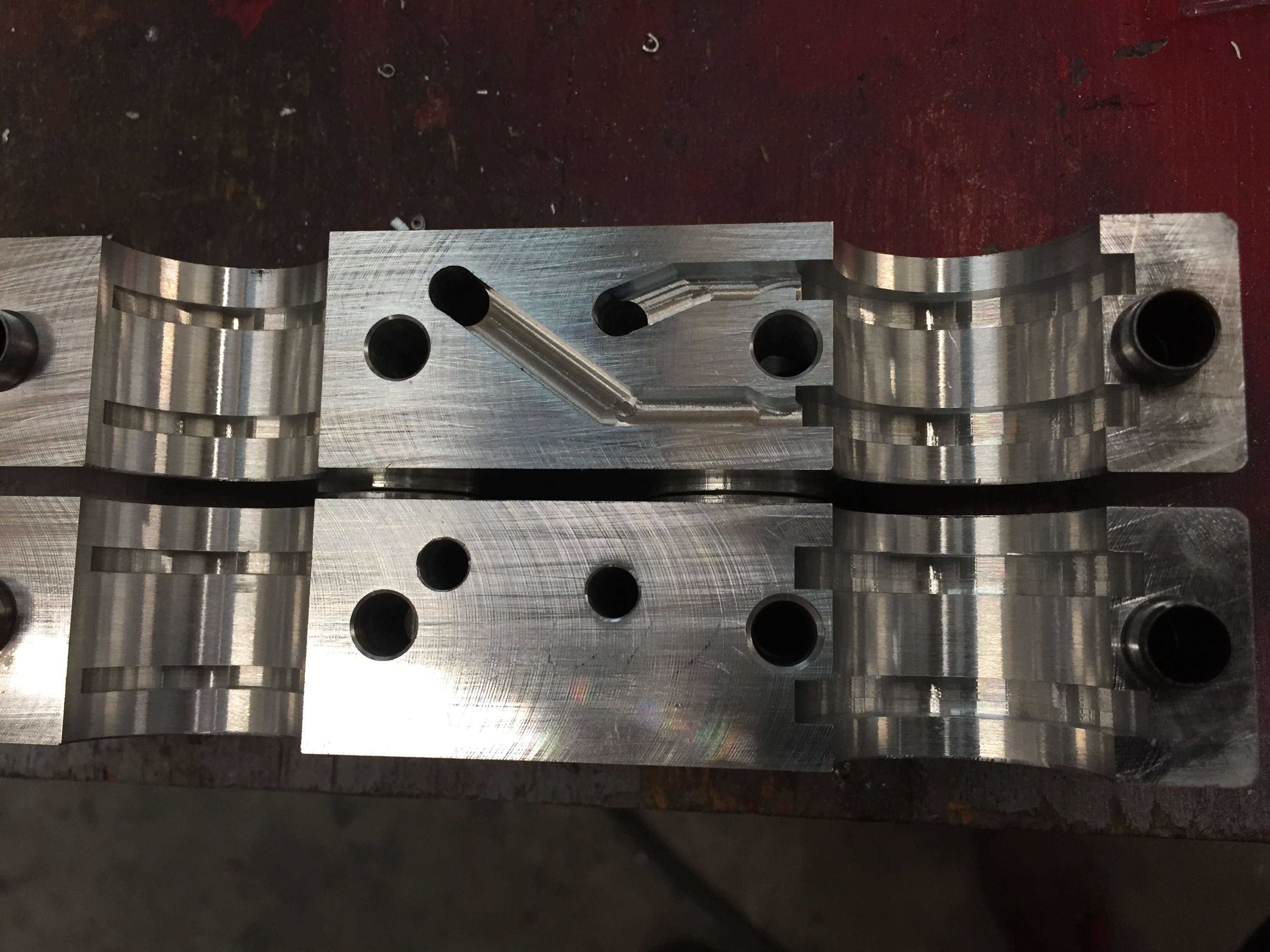

Here is a shot of two number one towers with the caps off. VCT on top and regular on the bottom.

The only modification to the head and cam towers to switch to VCT is to mill two channels from the 6mm holes out to the oil grooves. To be clear you will need VCT cams and all the timing and valving bits. My opinion on VCT is still that it’s probably an expensive gadget but I needed a new challenge and figured I’d see if I can make it happen. So if you are planning on a budget build I wouldn’t be holding out for VCT:)